-40%

JB Industries, Part# A32814, Line Tap valve "SOLDER ON STYLE" For 7/8" O.D. Tube

$ 7.65

- Description

- Size Guide

Description

Gregoriou Brothers Refrigeration Since 1979Frosty-Freeze

Line Tap valves "SOLDER ON STYLE" For 7/8" O.D. Tube

This listing is for One (1) Valve as pictured.

C & D Part# CD5578

JB Industries Part# A32814

M-Series Copper Saddle Valve

For 7/8" Tube

Hose connection is 1/4" male Flare with valve core

COPPER TO COPPER LINE TAP VALVES

Approved by Leading Manufacturers for ALL types of refrigerants

Eliminates costly, high-temperatue brazing

Installed with 95/5 or or lead low-temperature solder

Consists of;

Saddle body

Line piercing pin

Valve core

Teflon O-ring

Sealing cap

Valve is kept closed by spring loaded valve core.

Put sealing cap on for permanent seal

is for (1) Valve

MADE TO INSTALL ON A CHARGED LINE!

Follow directions below.

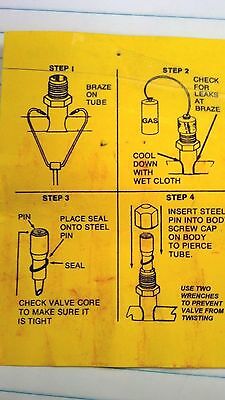

INSTRUCTIONS:

1) Clean tubing, apply flux and solder saddle valve body onto line for leak proof joint.

2) Allow joint to cool, clean joint and check valve for leaks

3) Place Telfon seal on shoulder of steel in which has valve core and insert into body.

4) Screw cap down on body forcing pin ti pierce line and crimp body. Use back wrench to avoid breaking braze joint. Tighten until body is crimped smoothly over top of pin.

5) Remove cap, attach hose and perform service.

6) When service is complete, wrench tight.

This listing is for One (1) Valve as pictured. C & D Part# CD5578 JB Industries Part# A32814 M-Series Copper Saddle Valve For 7/8" Tube Hose connection is 1/4" male Flare with valve core COPPER TO COPPER LINE TAP VALVES Approved by Leading Manufacturers for ALL types of refrigerants Eliminates costly, high-temperatue brazing Installed with 95/5 or or lead low-temperature solder Consists of; Saddle body Line piercing pin Valve core Teflon O-ring Sealing cap Valve is kept closed by spring loaded valve core. Put sealing cap on for permanent seal is for (1) Valve MADE TO INSTALL ON A CHARGED LINE! Follow directions below. INSTRUCTIONS: 1) Clean tubing, apply flux and solder saddle valve body onto line for leak proof joint. 2) Allow joint to cool, clean joint and check valve for leaks 3) Place Telfon seal on shoulder of steel in which has valve core and insert into body. 4) Screw cap down on body forcing pin ti pierce line and crimp body. Use back wrench to avoid breaking braze joint. Tighten until body is crimped smoothly over top of pin. 5) Remove cap, attach hose and perform service. 6) When service is complete, wrench tight.

Gregoriou Brothers Refrigeration Since 1979

Frosty-Freeze

Line Tap valves "SOLDER ON STYLE" For 7/8" O.D. Tube

This listing is for One (1) Valve as pictured.

C & D Part# CD5578

JB Industries Part# A32814

M-Series Copper Saddle Valve

For 7/8" Tube

Hose connection is 1/4" male Flare with valve core

COPPER TO COPPER LINE TAP VALVES

Approved by Leading Manufacturers for ALL types of refrigerants

Eliminates costly, high-temperatue brazing

Installed with 95/5 or or lead low-temperature solder

Consists of;

Saddle body

Line piercing pin

Valve core

Teflon O-ring

Sealing cap

Valve is kept closed by spring loaded valve core.

Put sealing cap on for permanent seal

is for (1) Valve

MADE TO INSTALL ON A CHARGED LINE!

Follow directions below.

INSTRUCTIONS:

1) Clean tubing, apply flux and solder saddle valve body onto line for leak proof joint.

2) Allow joint to cool, clean joint and check valve for leaks

3) Place Telfon seal on shoulder of steel in which has valve core and insert into body.

4) Screw cap down on body forcing pin ti pierce line and crimp body. Use back wrench to avoid breaking braze joint. Tighten until body is crimped smoothly over top of pin.

5) Remove cap, attach hose and perform service.

6) When service is complete, wrench tight.

This listing is for One (1) Valve as pictured.

C & D Part# CD5578

JB Industries Part# A32814

M-Series Copper Saddle Valve

For 7/8" Tube

Hose connection is 1/4" male Flare with valve core

COPPER TO COPPER LINE TAP VALVES

Approved by Leading Manufacturers for ALL types of refrigerants

Eliminates costly, high-temperatue brazing

Installed with 95/5 or or lead low-temperature solder

Consists of;

Saddle body

Line piercing pin

Valve core

Teflon O-ring

Sealing cap

Valve is kept closed by spring loaded valve core.

Put sealing cap on for permanent seal

is for (1) Valve

MADE TO INSTALL ON A CHARGED LINE!

Follow directions below.

INSTRUCTIONS:

1) Clean tubing, apply flux and solder saddle valve body onto line for leak proof joint.

2) Allow joint to cool, clean joint and check valve for leaks

3) Place Telfon seal on shoulder of steel in which has valve core and insert into body.

4) Screw cap down on body forcing pin ti pierce line and crimp body. Use back wrench to avoid breaking braze joint. Tighten until body is crimped smoothly over top of pin.

5) Remove cap, attach hose and perform service.

6) When service is complete, wrench tight.